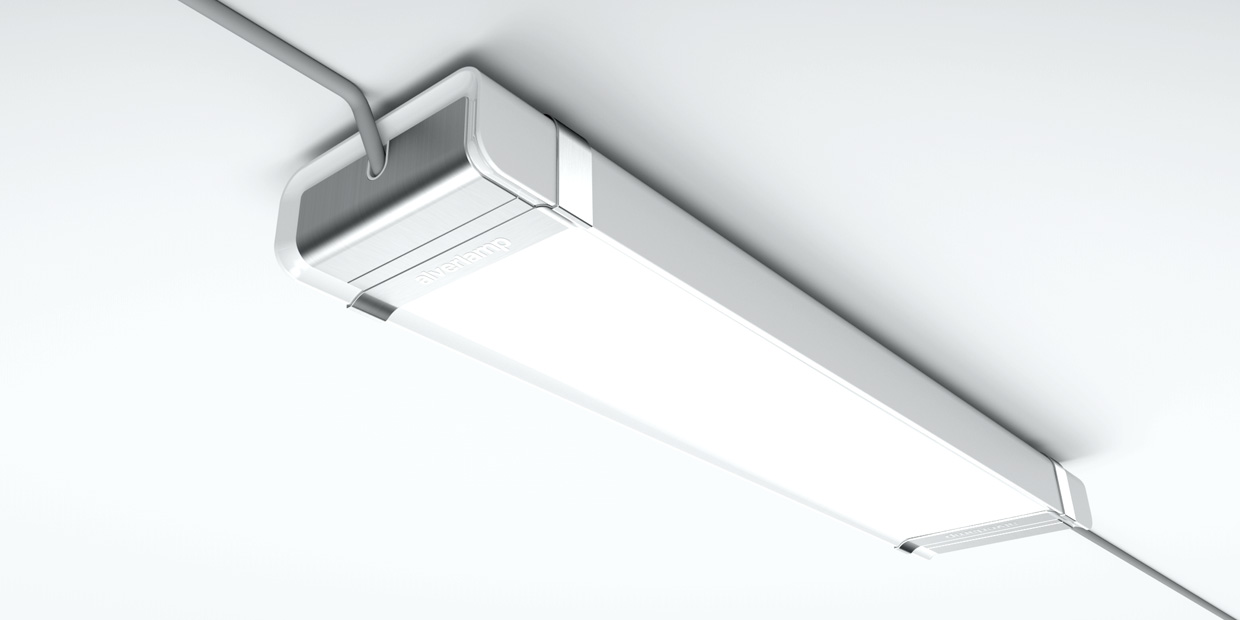

Alverlamp

IP67 LED lighting fixture range — innovation study

The primary goal for the creation of this range of lighting fixtures was to find ways to streamline manufacturing and reduce production costs, while offering a sleek design. Our designers also had to find solutions to facilitate the installation of the equipment and reduce their installation time. This installation time was very important in this study, because when it is necessary to equip a building or a parking lot of hundreds of devices, the reduction of the labor costs related to their installation, is a crucial factor in the purchase decision. Initially, the lighting fixtures were bound to be certified IP65, but finally the range was certified IP67, its design allowing a higher rating of protection against water/humidity.

The body of the lighting fixture is extruded in bi-material (opaque for the body, and transluscent to let the light), to reduce manufacturing costs, and ensure a better seal. With this mode of industrialization, a single mold is enough for the 3 sizes of products.

Exploded view of the product before the follow-up work with engineers.

Backstage of the project

Design requirements

At the start of the project, we worked with AlverLamp on the definition of the product, and we identified the importance to give on the time needed and easiness to assembly and mount the products.

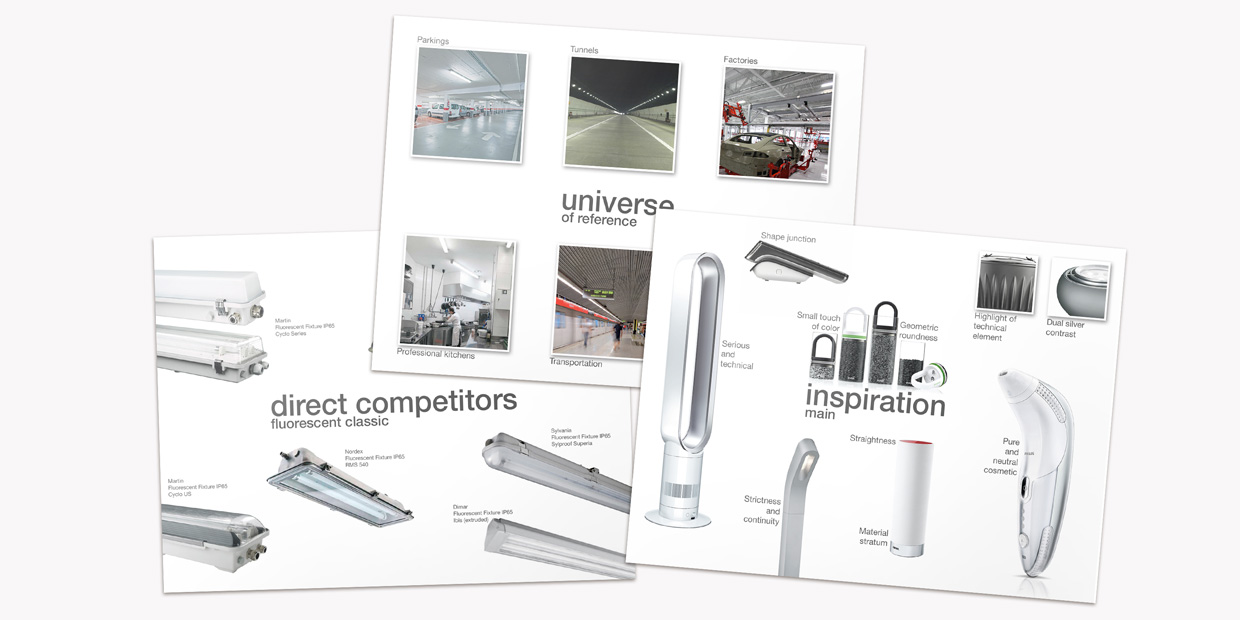

Market analysis

Excerpt from analysis market, with from left to right, part of the analysis of direct competitors, a visualization of the universe of reference, and a part of our trend boards.

Initial concept A, entry-level positioning

For this project, we have also given special attention to the positioning, working on three levels of positioning.

This concept offers an architecture that is all in continuity with the extrusion direction. It is simple, and shows a good balance of strictness and softness, the design being very round (oblong shape), but its roundness is counterbalanced by the strictness of the cap flat end and attachment parts. The body and cap are shiny white plastic, and the attachment are standing out in chrome. Screws and bolts are visible, to look a bit more technical. The branding is applied on the part that holds the aluminum plate supporting LED, which is inside the extrusion shell, that way, the printing is always clean and visible, behind the transparency shell of the product.

Initial concept B, mid-range positioning

This concept offers a very robust and simple architecture with its two end caps with a brushed-aluminum look that visually connects the product with the ceiling attachment part (also with brushed aluminum finish) to give a continuity/integrated look to the design. The global shape looks serious, and geometric, but with enough radiuses and details to ensure that the product does not look too sharp. The cable connector and screws are hidden behind aluminum covers to give to the lighting fixture a purer and unified look. The aluminum attachment parts receive the logo of the brand, which is laser engraved.

Mockup of the concept B

Realization of shape mockups in order to verify the geometries, prior to finalization of the design.

Initial concept C, high-end positioning

This concept offers a very distinctive architecture, which stands out from the ceiling. It highlights the extruded shape, and has a shape junction effect with its radius bent shape at both ends. The fixture attachment and enclosing parts are mat aluminum, to make standing out the 4 cover parts (2 per end) which have a vertical brushed aluminum finish to give to the fixture a very robust feeling. Screws and bolt are hidden, so the global shape of the fixture also looks purer and more elegant. The branding is laser engraved on a chrome part, to make it look high end.