Does this sound familiar to you?

-

Too many providers.

-

Way too much time lost in communication.

-

Too hard to move forward efficiently.

-

Many mistakes occur at the end because of lack of anticipation, therefore riskier investments.

-

No global accompaniment.

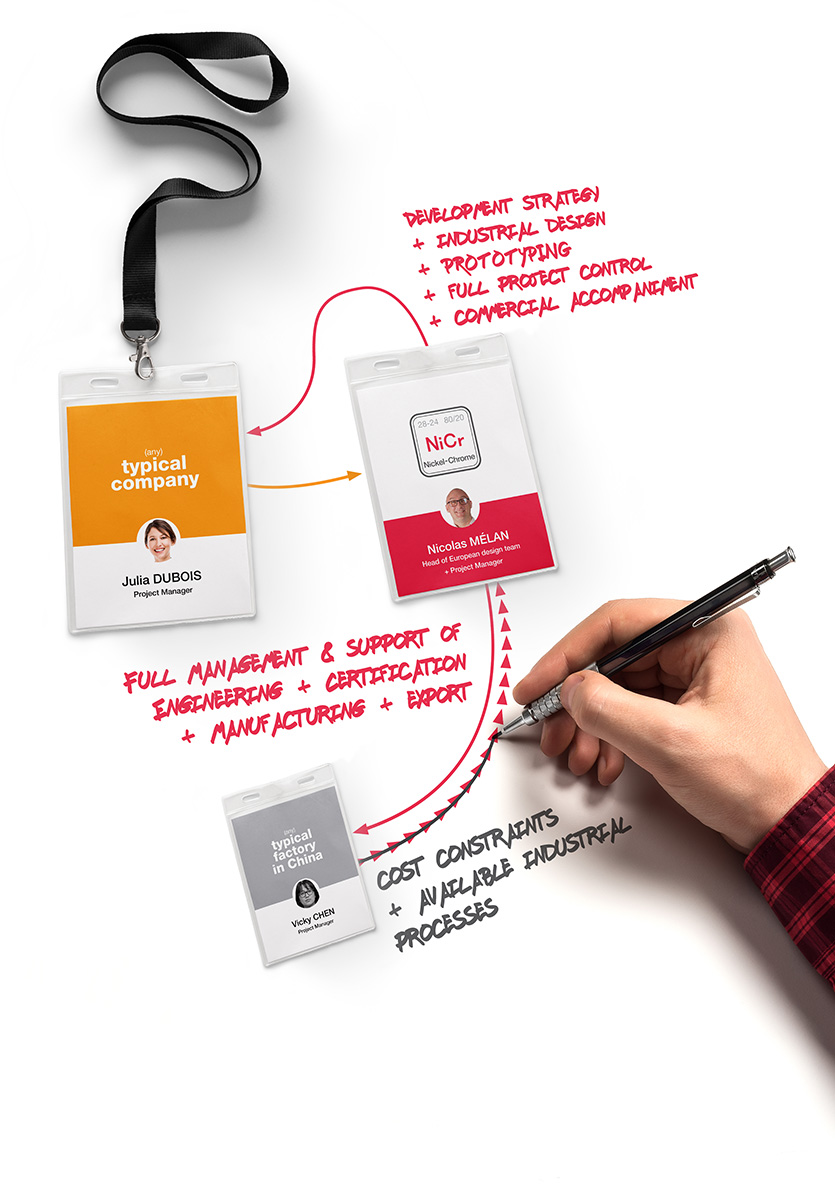

The ideal solution: one provider to handle everything for you…

-

One provider + one factory, that’s it.

-

Everything is simpler & faster.

-

Maximum anticipation for maximum safety of product development investments.

-

Full global accompaniment.

European skills & mindset in China

It is crucial for our project managers, designers, engineers and quality control experts to know and understand the expectations of our clients’ managers. That is why our lead designers are Europeans. Not just for their skills, but also their mindset, their understanding of European consumers’ needs and European market trends.

Our directors and managers are all European born / studied in Europe / worked for or with European companies for many years. We know very well that loss in translation is never only a matter of language, but also a matter of culture and experience.

No timeout in conception

No time is lost to check technical solutions, trying to have everyone in Europe available for meetings, waiting for samples or travelling to factories abroad. We are in China, either on-site or there in a couple of hours to find and test the solutions. And your reports of our activity are just a click away.

Our industrial design teams work exactly like an in-house design department. They work in close relationship with your strategic marketing department in Europe, but remotely from China, which is now very easy. That way, they can be more efficient, using the full benefit of their technical know-how and design to cost skills by being close to the factories that will manufacture your products.

6x times more secured developments

Developing products involves lots of investments in time, technologies, moulds, raw materials, intellectual property, manufacturing, packaging, certifications, marketing, transport… So, any problem being found at a late stage involves massive time and money loss. It is even more if you count (and you definitely should) the late arrival on the market, the loss of revenues and the potential loss in market shares. And, if a product sells poorly, it will take a lot of time before a new product can replace it. Therefore, any process to secure the product development process is not only a safe investment, but a growth factor.

1. With our design team + your design team, we have twice the chance to finalise a great design.

2. Our systematic assessment of your supplier’s engineering and manufacturing capabilities ensures that our design teams are set to work with your exact capabilities in mind. So you are sure to be able to manufacture all our designs.

3. Our optimisation process of design to cost guarantees both a simpler, faster and secured engineering and manufacturing stages. So you can afford the design and keep or increase your margins.

4. Our very close‑up management of engineering and manufacturing follow‑up, along with our reports at all steps, helps you to keep a close control of the whole process.

5. Our certification and export support reinforce the safety of your manufacturing and shipping processes.

6. With your time to market being reduced and the reliability of the development process being increased, your financial risk is less than ever.

An ally at all steps

Before Nickel‑Chrome, clients had to make all decisions alone without any overall support. They were supposed to know everything and be sure that they never missed anything, sometimes having to manage various external partners at each stage. And without any single external eye capable of understanding and perceiving everything they had to handle. This time is over.

Nickel‑Chrome provides clients with advice and support on a global scale. We are at your side at all steps so you can be sure to take all the best decisions. For all the projects you entrust us, we take care of everything thanks to our comprehensive process and you have a single contact person to manage and discuss every part of your project.

Nickel‑Chrome is responsible for the whole development process, from the beginning to the end, including help on the marketing launch. We know it is the only way to make sure that all products are matching the consumers’ expectations, your brand image and being profitable for you.

Nickel‑Chrome is simply the easiest way to create new products in a reliable, fast and economical way. We do all the industrial design internally, with engineering, manufacturing quality and cost control in mind since the beginning. We then manage all the engineering and manufacturing done by your factories in China. We provide guidance, technical support, but also all the project management and follow‑up, so your suppliers’ engineers, machines and workers work in the most efficient and qualitative way.

We are always available to provide you help and a relevant external eye for all your product development decisions. Because we’re an ally, not just a partner.

An efficient accompaniment suited to all industries

We are here to help you on the following industries: home appliances, lighting, electronic consumer goods, electrical appliances, baby products, toys, cookware, furniture, tools… would you be startups, SMEs or large international groups.

A turnkey service

Nickel‑Chrome offers you a turnkey service, from design to engineering, prototyping and manufacturing, all through a single contact person, all remotely. Our product development service is all made to be efficient, reliable and stress-free manufacturing, while being cost-effective.

Potential risks without us

Let’s make things clearer with typical risks of a classic product development with a client left alone with a factory…

1. Requirements are taken as is and more than 85% of the time, the requirements are missing information that leads to a loss of money. Time is lost in product development, which means more costly developments. Therefore, time to market is increased and, with it, fewer sales & profits, but also more risks: potential price increase in raw materials or components + reduced product lifecycle as the product missed its ideal launch time.

2. The initial design is matching the brand DNA, but the factory can’t make the design as is, so multiple revisions are required. More and more of the initial design spirit and appeal is lost along the way. Finally, either the design is too altered to be appealing to consumers and the brand, or it would be too expensive for the market. The brand could not reduce its margins and could not risk launching a product that would be perceived as too expensive for the brand. Therefore, a whole product development has to be done again, which means lots of time, money and time to market are lost.

3. Client is alone to take all decisions, as external partners are only responsible for their work. So, sometimes, mistakes are made with some crucial elements during commercial launch. A packaging that ruins the user experience, or advertising with poor arguments in favour of the product, for example.

Concrete benefits of our concept

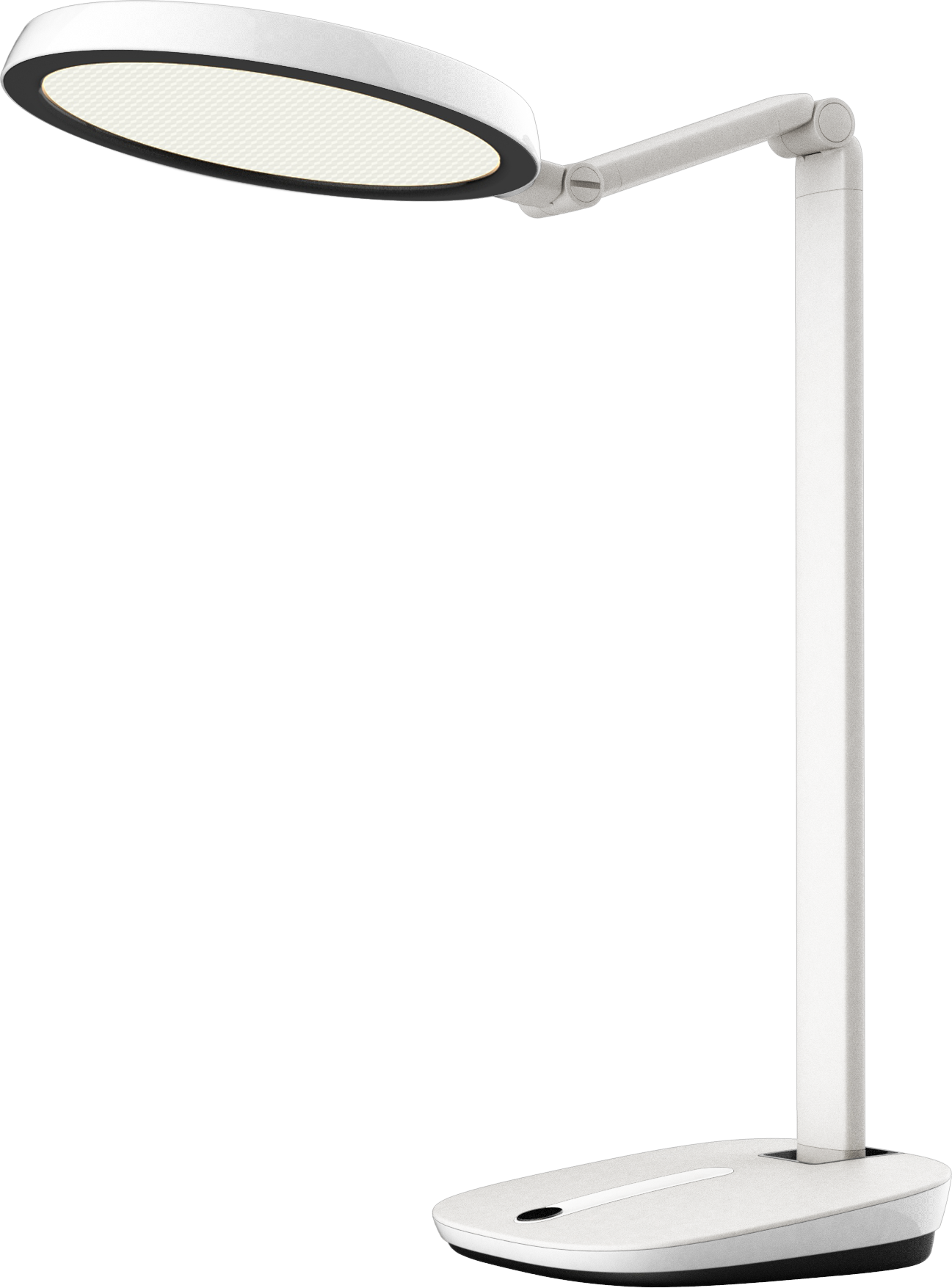

Let’s make things clearer with some business data based on a real case scenario for a desk light for Philips…

1. Requirements are clearly understood and fully matured, as they are developed in a joint effort between the client and us. Magnetic head feature was invented by us and jointly developed with Philips. The product was released on the market as planned, with no extra costs. Desk light has a long product lifecycle (3 years so far), 200 000 pieces were sold, for a total of 60 million RMB, for a margin of 13,2 million RMB for Philips.

2. The initial design was right on track regarding both the design language / brand DNA and the manufacturing costs. So, no surprises for Philips and a simple product development (6 months), as the product gets better and better with the joint efforts / comments from Nickel-Chrome and Philips design and engineering teams. The factory can manufacture the product without any problem or unexpected costs.

3. Additional support is always available, so we designed a smart packaging and helped to find the product name. But we could also have helped with advice on additional CMF or the product page web design / advertising, for example. As we were involved since the very beginning, it is always easy for us to bring our clients a relevant external perspective and advice at every step.