Engineering & certification management:

a reliable process

Our engineering & certification management process was built on the best practice of international companies in different industries so it could match or exceed all European companies’ needs.

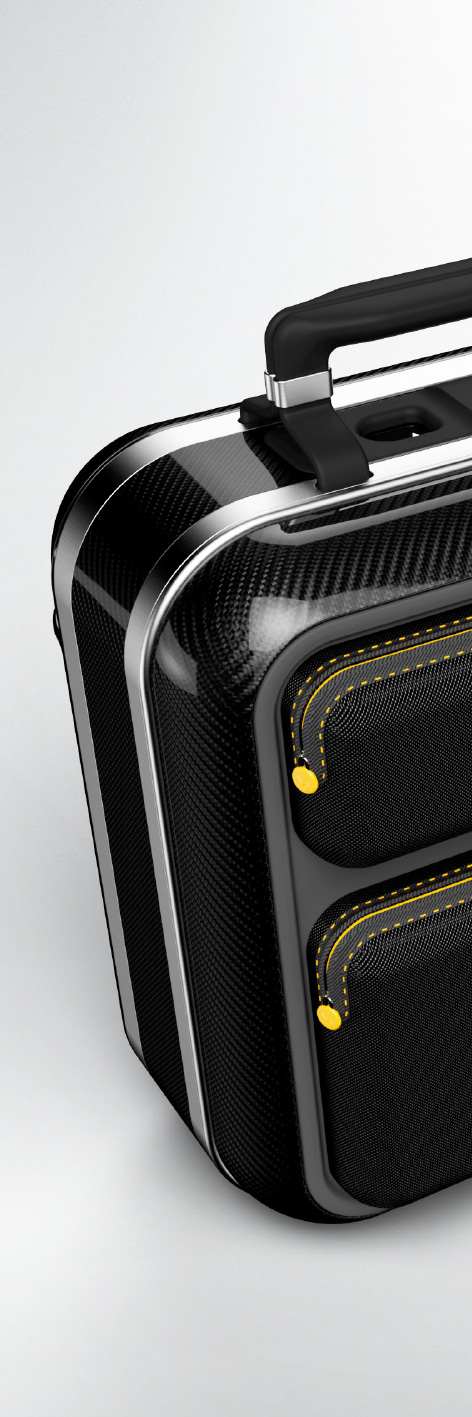

Nickel-Chrome’s engineering & certification management process is the best way to make sure the validated designs are developed the right way, respecting the design intentions and the brand image. Why? Simply because it is the same teams who designed them who are in charge of managing the development. It is also the safest way for clients to keep their developments in China under control, with planned & clear reports and experts supervising, advising, guiding and reporting everything at each step; all so there is no room for errors or loss of time during the development and certification.

Our approach

We are working with an international iterative engineering process. Therefore, each stage is validated and approved by you before going to the next.

Having those regular check points is the best way for you and us to control the progression of the projects. At each stage, we give you our explanations, justifications and recommendations, as engineering must remain pragmatic at all times and in regards of objective criteria.

Our 10 stages iterative process

Our process is iterative; we validate each stage before going to the next. It starts with the engineering of the validated design. It finishes with the trial production.

Stage 1: Engineering requirements

Establishing the engineering requirements with the objectives and constraints of the project in regards to engineering.

Stage 2: Preliminary engineering

Evaluating the technical feasibility of design, conducting risk assessment and estimating the manufacturing costs of the design.

Stage 3: Prototype testing

Making the prototype(s) in the best conditions, for maximum cost efficiency & reliability.

Taking all the opportunities of learning and optimisation possible.

Stage 4: Certification preparation

Preparing all the necessary documents for the certification so it can have the maximum chances of success.

Stage 5: Prototype optimisation

Optimising all aspects of the prototypes: reliability, appearance, practicality, reliability, comfort… but also cost optimisation to give product(s) best chances of success.

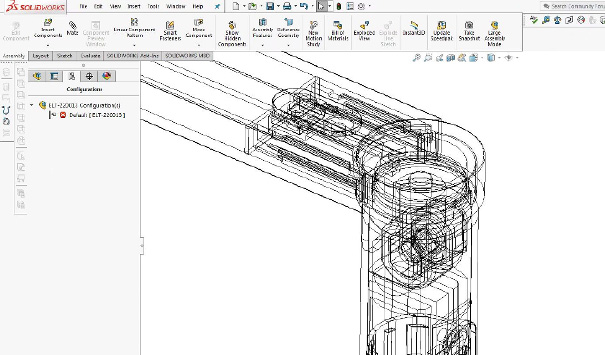

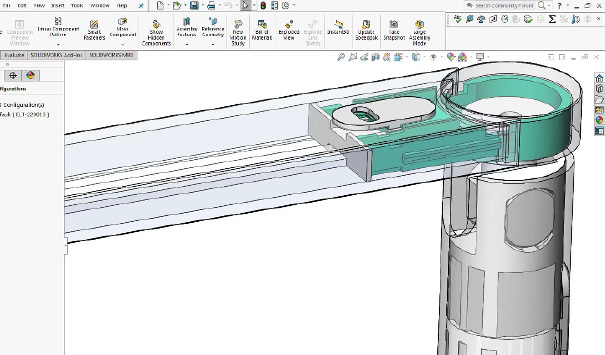

Stage 6: Final engineering CAD files

Updating the bill of materials and validate the list of potential suppliers.

Create the final engineering CAD files.

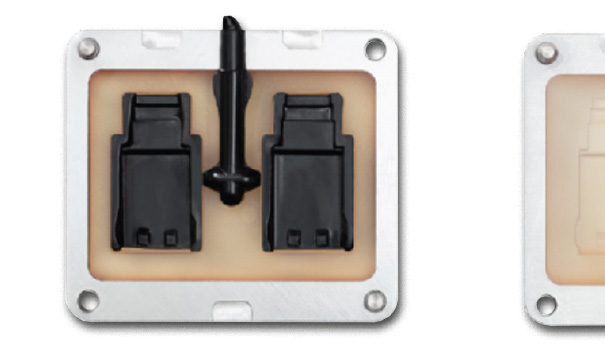

Stage 7: Mould making & testing

Creation of the 3D files for the moulds and tooling. Validate the files for the moulds and tooling.

Creation of the moulds + tooling & testing.

Stage 8: First shooting samples + certification

Producing the first shooting samples & packaging to conduct internal tests to optimise production.

Submission of documents to the certification lab.

Stage 9: Certification reconciliation

Reconciliation of all the certification documents and upload to the client’s server.

Stage 10: Trial production

Organise the production and check that all the raw materials and components match the standards defined earlier.

Managing the trial production.

Detail of our

engineering & certification process (ironclad mode)

Our 4 different services for

engineering & certification

Standard engineering study

(lean mode)

A standard engineering study is used to guide and support a factory’s engineering department in the development of a new design, but on a kind of product the factory already has experience with. This engineering study’s purpose is to secure the whole process of product development, making it more reliable and its investments safer, but with a shorter time to market. The lean mode of the standard engineering study removes the NONESSENTIAL paperwork and checkpoints for a faster time to market and a more cost-efficient development. This engineering study is very efficient and compatible with most factories.

Nickel-Chrome make sure the approved design is engineered in the best way, so that it respects the design spirit, features, ergonomics, style, factory & retail price… Nickel-Chrome designers join their efforts with Nickel-Chrome engineers to help in the technical development of the product. We provide assistance and advice, and, if needed, modify the design to better match the final technical constraints. We advise and report to the client on the progress made by its factory in the development of the product.

Cost optimisation also plays a big role in this study, which is intended for short term manufacturing.

Standard engineering study (ironclad mode)

A standard engineering study is used to guide and support a factory’s engineering department in the development of a new design, but on a kind of product the factory already has experience with. This engineering study’s purpose is to secure the whole process of product development, making it more reliable and its investments safer. The ironclad mode of the standard engineering study increases the development time but provide clients a fully documented development at all steps, with the maximum reports and checkpoints possible, for a total control over it. The ironclad mode should only be used by clients with the most demanding project management process and factories used to such high-end process.

Nickel-Chrome make sure the approved design is engineered in the best way, so that it respects the design spirit, features, ergonomics, style, factory & retail price… Nickel-Chrome designers join their efforts with Nickel-Chrome engineers to help in the technical development of the product. We provide assistance and advice, and, if needed, modify the design to better match the final technical constraints. We advise and report to the client on the progress made by its factory in the development of the product.

Cost optimisation also plays a big role in this study, which is intended for short term manufacturing.

Advanced engineering study

(lean mode)

An advanced engineering study increases the scope of a standard engineering study, as it is used to guide and support a factory’s engineering department in the development of the design of a kind of product the factory has no experience with. This engineering study’s purpose is to secure the whole process of product development, making it more reliable and its investments safer. The lean mode of the advanced engineering study removes the NONESSENTIAL paperwork and checkpoints for a faster time to market and a more cost-efficient development. This study is very efficient and compatible with most factories.

Nickel-Chrome make sure the approved design is engineered in the best way, so that it respects the design spirit, features, ergonomics, style, factory & retail price… Nickel-Chrome designers join their efforts with Nickel-Chrome engineers to help in the technical development of the product. We provide reinforced assistance and advice, and, if needed, modify the design to better match the final technical constraints. We advise and report to the client on the progress made by its factory in the development of the product.

Cost optimisation also plays a big role in this study, which is intended for short and midterm manufacturing.

Advanced engineering study (ironclad mode)

An advanced engineering study increases the scope of a standard engineering study, as it is used to guide and support a factory’s engineering department in the development of the design of a kind of product the factory has no experience with. This study’s purpose is to secure the whole process of product development, making it more reliable and its investments safer. The ironclad mode of the standard engineering study increases the development time but provide clients a fully documented development at all steps, with the maximum reports and checkpoints possible, for a total control over it. The ironclad mode should only be used by clients with the most demanding project management process and factories used to such high-end process.

Nickel-Chrome make sure the approved design is engineered in the best way, so that it respects the design spirit, features, ergonomics, style, factory & retail price… Nickel-Chrome designers join their efforts with Nickel-Chrome engineers to help in the technical development of the product. We provide reinforced assistance and advice, and, if needed, modify the design to better match the final technical constraints. We advise and report to the client on the progress made by its factory in the development of the product.

Cost optimisation also plays a big role in this study, which is intended for short and midterm manufacturing.