Industrial design, a solid heritage : sketching to think faster

Our industrial design process is totally based on what our peers established, almost a century ago. Why? Simply because it has been working perfectly for so long…

… and also because, in order to achieve best results, the design process needs to be respected to the letter. At Nickel‑Chrome, we know very well that there is no such thing as designers who specialise in one type of item. Industrial designers can design almost anything. And the only difference of skills between designers is the experience they have with the design process and its constant application on different products, markets, brands and positioning. We also stress out that if industrial designers are sketching, it is only because it is, so far, the fastest way available for them to conceive a product from scratch. Sketching is a tool to them, not an intention.

Our approach

We are working with an international iterative design process. Therefore, each stage is validated and approved before going to the next.

Having those regular check points is the best way for you and us to control the progression of the projects. At each stage, we give you our explanations, justifications and recommendations, as industrial design must remain pragmatic at all times and in regards of objective criteria.

Our 5 stages iterative process

Our process is iterative; we validate each stage before going to the next. It starts with the very first idea. It finishes with the final adjustments for manufacturing.

Stage 1: Design requirements

Definition of your objectives & constraints and potential issues.

We build together the right frame for your project, so we can enrich it with our long experience from the very beginning.

Stage 2: Analysis

We analyse your market (direct competitors, indirect competitors), as well as the usage scenarios for the products to be designed.

We also analyse the design trends. We do this so we can know your market and enrich our creativity with pragmatic & useful insights.

Stage 3: Creative research

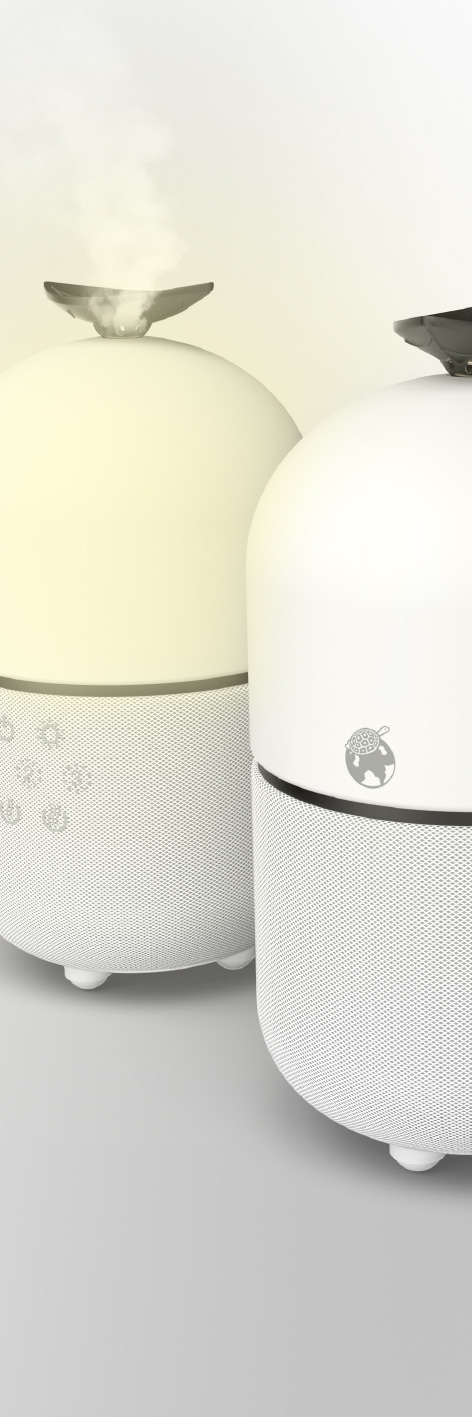

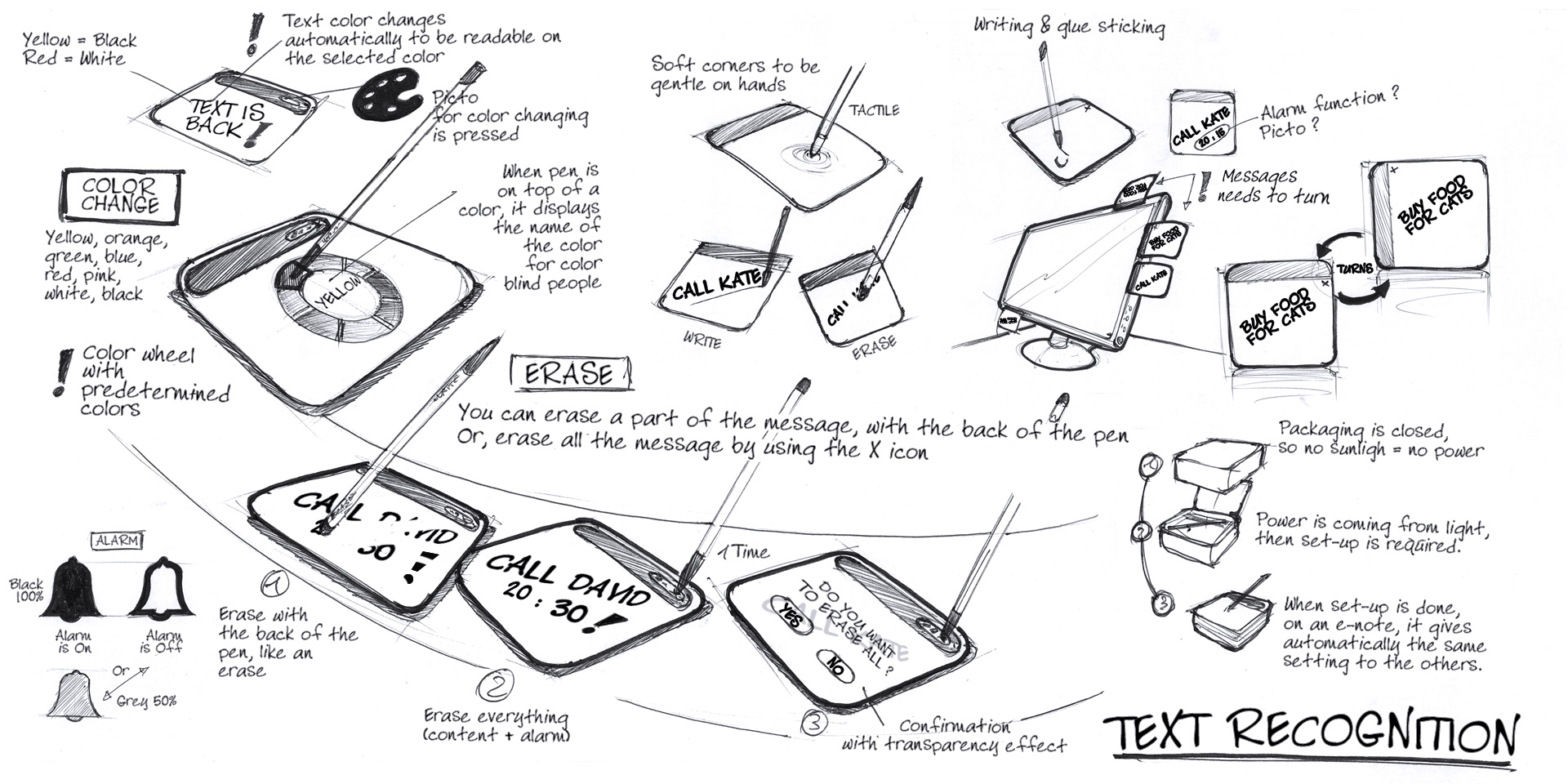

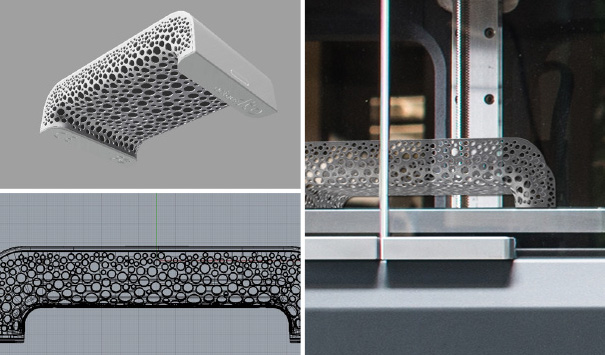

We start the research with sketching and we continue it with 3D CAD drawings.

We eliminate the unsatisfying concepts and we refine the promising ones. That way, we can present you only good concepts to choose from.

We also create mock-ups.

Stage 4: Design finalisation

From your validated choices and comments, as well as what we learnt from the mock‑ups done in stage 3, we refine and optimise the design in its details, including its cosmetics intended for manufacturing.

Then, when everything is fine, we export our 3D files to engineers and/or factories.

Stage 5: Follow-up

We work with engineers to solve all technical problems and final cost problems.

We also adapt the design, if necessary.

We continue by optimising the cosmetics of the products, as well the first shooting samples, so your products look & feel as good as they can be.

Detail of our industrial design process

Our 4 different services in

industrial design

Standard design study

A Standard Design Study focuses on the attractiveness and relevance of your products. It is the simplest way to design good products.

We integrate all the technical and ergonomic specifications to meet the functional requirement of your product but do not challenge the overall product architecture.

This type of study is intended for short-term manufacturing.

Product identity design study

A Product Identity Design Study increases the scope of a Standard Design Study in order to develop your brand identity through new products. The aim is to reinforce the presence of your brand on the marketplace with stronger and more recognisable design codes enabling customers to identify your brand better through your products.

Once we have created a more attractive and consistent brand image, your new product identity will become a baseline for future product development.

This type of study is intended for short and midterm manufacturing.

Innovation design study

An Innovation Design Study increases the scope of a Standard Design Study in order to build new products and solutions. Reassessing customer needs and product uses, we completely rethink your product in order to design truly innovative products.

To do this, we rework design conceptualisation and product architecture as well as aesthetics, and we incorporate your brand design codes. Your products will be more innovative, not necessarily just technically or technologically. They will be better suited for consumer use and more impactful than those of your competitors.

This type of study is intended for short and midterm industrialisation.

Prospective design study

An Innovation Design Study increases the scope of a Standard Design Study in order to build new products and solutions. Reassessing customer needs and product uses, we completely rethink your product in order to design truly innovative products.

As industrial designers, we use and develop our analytical skills every day and for many different brands and products. This allows us to:

- identify and harness current and potential technological advances,

- monitor social and societal developments and project their impact in the near future,

- understand current trends and explore future developments,

- define your brand image and imagine its future development,

- create new product-concepts based on these criteria (purpose, uses, style, etc…).

This type of study is intended for long‑term manufacturing.