Manufacturing & export management:

a reliable process

Our manufacturing & export management process was built on the best practice of international companies in different industries so it could match or exceed all European companies’ needs.

Nickel-Chrome’s manufacturing & export management process is the best way to make sure the engineered designs are manufactured the right way, respecting both the brand image and the defined golden samples. Why? Simply because it is the same teams who designed the products who are in charge of managing their manufacturing. It is also the safest way for clients to keep their developments in China under control, with planned & clear reports and experts supervising, advising, guiding and reporting everything at each step; all so there is no room for errors or loss of time during the manufacturing and export.

Our approach

We are working with an international iterative manufacturing process. Therefore, each stage is validated and approved by you before going to the next.

Having those regular check points is the best way for you and us to control the progression of the projects. At each stage, we give you our explanations, justifications and recommendations, as engineering must remain pragmatic at all times and in regards of objective criteria.

Our 4 stages iterative process

Our process is iterative; we validate each stage before going to the next. It starts with the ordering of the golden samples. It finishes with the export management.

Stage 1: Golden samples ordering

Review of all the product documentation and update it (if necessary).

Reconciliation of all the product documentation and confirmation with all parties. Order the manufacturing of the golden samples.

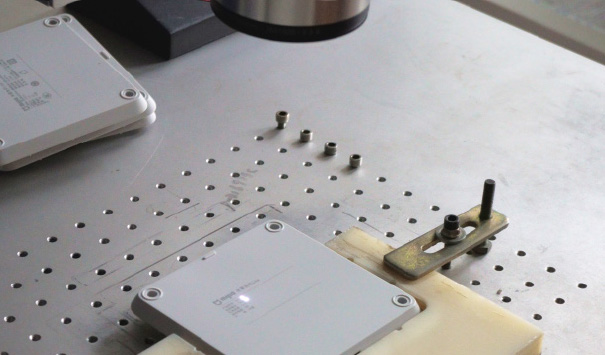

Stage 2: Golden samples creation

Manufacturing and validate the golden samples which will be the reference for quality control during all the mass production.

Stage 3: Mass production

Gathering in one place all the documents needed and complete the first order of mass production. Inspect the first order, so the factory can then complete all the other orders alone.

Stage 4: Export management

Checking the factory has prepared all the documents for the customs and arranged for shipping the products in good conditions.

Report to the client. Random product inspections. Supervision of the process of containers loading.

Detail of our

manufacturing & export process (ironclad mode)

Our 4 different services for

manufacturing & export

Standard manufacturing

(lean mode)

A standard manufacturing is used to guide and support a factory in the manufacturing of the client’s product, but on a kind of product the factory already has experience with. For example: a kettle that replaces the model they were producing for the last 5 years. The lean mode of the standard manufacturing removes the NON-ESSENTIAL paperwork and checkpoints for a faster and more cost-efficient manufacturing. This manufacturing service is very efficient and compatible with most factories.

Nickel-Chrome provide assistance, guidance and advice to the factory at all steps and provide regular and objective reports to the client, for an easy and stress-free mass manufacturing. Nickel-Chrome make sure the golden samples respect all the defined standards and, later that the manufactured products match the validated golden samples.

In the case of continuous or multiple mass manufacturing sessions, Nickel-Chrome will conduct spontaneous inspection, to make sure all procedures in place and quality of raw materials are still in place.

Standard manufacturing

(ironclad mode)

A standard manufacturing is used to guide and support a factory in the manufacturing of the client’s product, but on a kind of product the factory already has experience with. For example: a kettle that replaces the model they were producing for the last 5 years. The ironclad mode of the standard manufacturing increases the manufacturing time but provide you a fully documented process at all steps, with the maximum reports and checkpoints possible. The ironclad mode should only be used by clients with the most demanding project management process and factories used to such high-end process.

Nickel-Chrome provide assistance, guidance and advice to the factory at all steps and provide regular and objective reports to the client, for an easy and stress-free mass manufacturing. Nickel-Chrome make sure the golden samples respect all the defined standards and, later that the manufactured products match the validated golden samples.

In the case of continuous or multiple mass manufacturing sessions, Nickel-Chrome will conduct spontaneous inspection, to make sure all procedures in place and quality of raw materials are still in place.

Advanced manufacturing

(lean mode)

An advanced manufacturing is used to guide and support a factory in the manufacturing of the client’s product, but on a kind of product the factory has no experience with. For example: a food processor with built-in scale and led light for a factory who never made food processors. The lean mode of the advanced manufacturing removes the NON-ESSENTIAL paperwork and checkpoints for a faster and more cost-efficient manufacturing. This manufacturing service is very efficient and compatible with most factories.

Nickel-Chrome provide assistance, guidance and advice to the factory at all steps and provide regular and objective reports to the client, for an easy and stress-free mass manufacturing. Nickel-Chrome make sure the golden samples respect all the defined standards and, later that the manufactured products match the validated golden samples.

In the case of continuous or multiple mass manufacturing sessions, Nickel-Chrome will conduct spontaneous inspection, to make sure all procedures in place and quality of raw materials are still in place.

Advanced manufacturing

(ironclad mode)

An advanced manufacturing is used to guide and support a factory in the manufacturing of the client’s product, but on a kind of product the factory has no experience with. For example: a food processor with built-in scale and led light for a factory who never made food processors. The ironclad mode of the advanced manufacturing increases the manufacturing time but provide you a fully documented process at all steps, with the maximum reports and checkpoints possible. The ironclad mode should only be used by clients with the most demanding project management process and factories used to such high-end process.

Nickel-Chrome provide assistance, guidance and advice to the factory at all steps and provide regular and objective reports to the client, for an easy and stress-free mass manufacturing. Nickel-Chrome make sure the golden samples respect all the defined standards and, later that the manufactured products match the validated golden samples.

In the case of continuous or multiple mass manufacturing sessions, Nickel-Chrome will conduct spontaneous inspection, to make sure all procedures in place and quality of raw materials are still in place.