Sun East

SMT printer S510 — product identity study

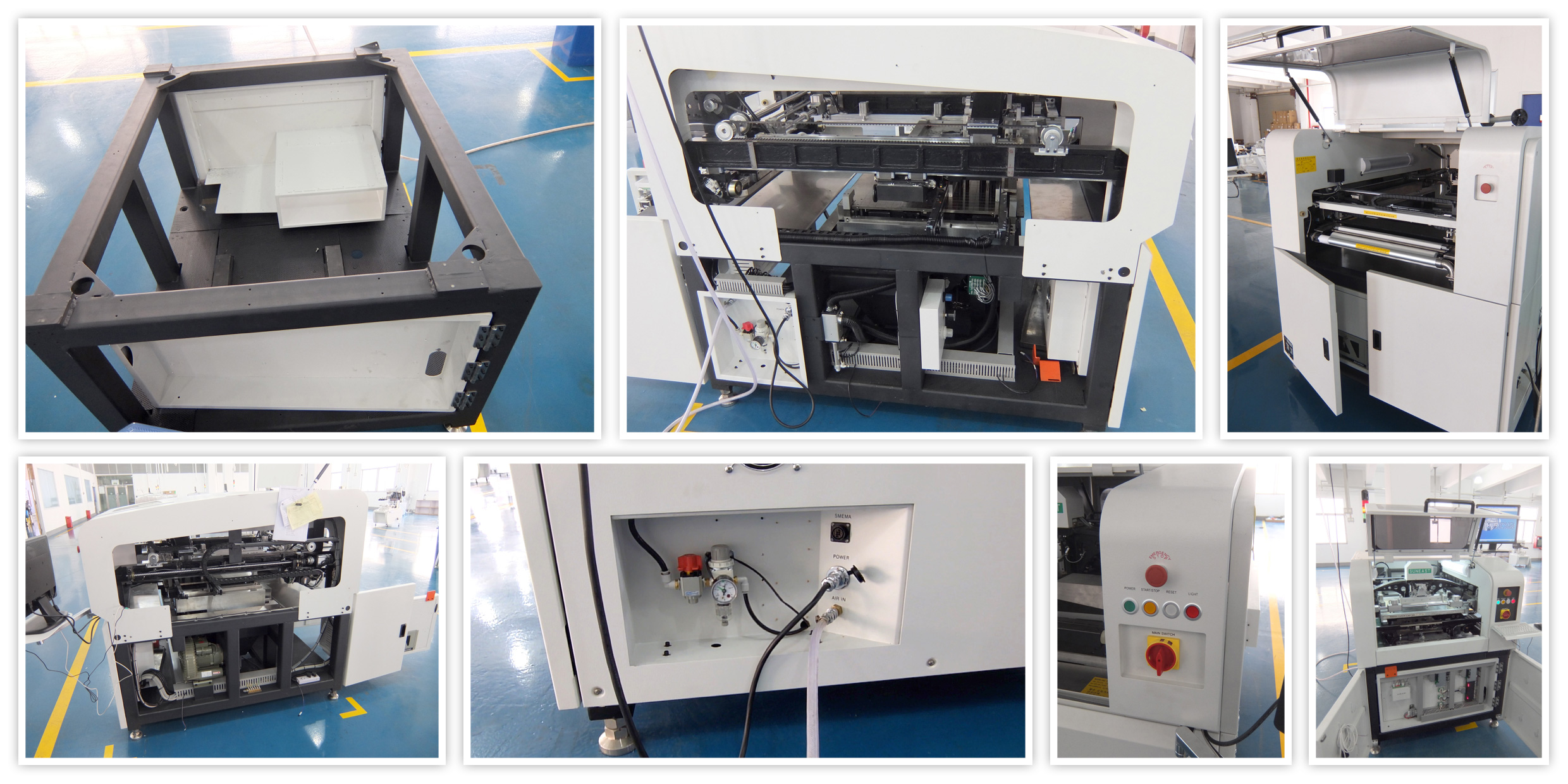

Imagine the new product-identity of Sun East, industrial equipment manufacturer for its new generation of SMT printer (machine for PCB printing). A SMT printer does not work alone, it is part of a production line, consisting of a loading machine, the SMT printer that create the PCB, a control module, one or more machines to insert and solder the components on the PCB, an oven to dry the PCB & components, and a machine that checks the quality of the PCB.

It was therefore necessary to design a machine that fits easily in this set. The challenge was also to give a true product-signature, easily identifiable and recognizable, but not easy to copy by companies reselling Sun East machines under their own brand, by simply changing the doors marked with the Sun logo East. Compared to the previous generation of machines, one constraint was to use folded metal sheet for the cover panels and to minimize the use of bolts and screws to fix them.

The overall architecture consists of 4 extruded aluminum columns, which give to the machine a very serious aspect, professional and qualitative. These corner units are like an “exoskeleton”, and give a very stable look. Each Sun East machines would use the same elements, which could be adapted in height, and thus be declinable on all their machines. These elements contribute, beyond any graphic or logo color (too easily replaceable) to clearly identify a Sun East machine. The width of the machine has been reduced and its height has been slightly increased to give it more elegant proportions.

Creation of an impacting color code. Black satin body (already used on the chassis of the machine) and a red belt (from the red of the brand’s logo). This belt allows to visually separate the working area from the maintenance area. It also brings the support arm for the monitor, keyboard and mouse.

We provided ergonomic solutions for easy installation, usage and maintenance of the machine. We brought also better ergonomics to the control monitor, keyboard and mouse thanks to a new adjustable support arm, for better visibility of the screen by the technician. The support arm also provides a clever management of computer cables and easy access to connections. The access doors have larger openings, for a better visual control of the machine’s work.

The cable connectors are regrouped in one single location for an easier installation of the machine. Feet are adjustable to improve stability and balance of the machine. We implemented storage space in the lower front part of the machine. The lower side panels now have locking systems, in addition to handles, to ensure that only authorized personnel can open and access the technical parts of the machine. The upper side panels are equipped with magnets and handles to be easily removed by the technician, if necessary.

Additional cosmetic.

Backstage of the project

Machine analysis and design requirements

On site analysis, at Sun East, Shenzhen (China), to understand what is an SMT printer: purpose, set-up, usage, but also conception, industrialization, industrial processes mastered by the client, classical assembly principles…

From there, we can better understand the constraints and needs of Sun East, and establish with them relevant design requirements.

Direct competitors — Local / Mapping

Market analysis highlight a distinction between local competitors (Chinese) and Overseas competitors. The first thing to note is that most competitors do not offer really attractive machines in the SMT printer market.

Local competitors do not provide a really attractive design, but some, like FolungWin and HDGD focuses on the exterior style of their machines. It is the same for Oversea competitors, except for companies like Speedline and Mydata. Dek, international competitor offers a style that brings a difference, but failed to come up with an attractive and professional design to its machine. Only Ekra, Fuji and Sony / Juki managed to bring attractive designs and strong identities for some of their machines.

The most attractive design identity on the market is provided by Ekra for its Serio 4000. The most consistent design identity is from Sony, for its range Saxes, all the machines sharing the same product-identity.

Project trend axis

First remarkable element: modern machines have a cosmetic made of 2 or 3 colors maximum. Strong contrasts are often used, as well as qualitative materials (Eol, Datron, Kuka, Metal Industries Wrench …). The shapes vary, but the idea of clear line of strength is always present. Machines are showing sobriety and rationalism (Eol, ProJect). They have an architecture that is either monolithic or showing distinctive areas for the doors, maintenance, or work areas (Eol, Datron).

The trend is also to have a significant impact on the brand image with qualitative details/materials (Huawei, Kuka). In this case, the support element of the branding give a structuring effect, and becomes an integral part to the style of the machine, instead of being just a printing, or a replaceable plate on the machine. Cable management and ergonomics of the terminal access have improved in general, so special attention should be brought to this part (Aures).

Brand values

Illustration of brand values of the company Sun East, with its definitions and, for each, value a formal illustration, which allows a better overview of the brand and its universe. Those values will be formalized during the design research stage.

Advanced: A machine that is superior in comparison to its peers. It involves an evolution of possibilities through forward thinking, in order to bring cutting edge achievements. It goes beyond High Tech, as it does not rely solely on technology, but also on thinking, usage, results, and style as well.

Professional: A machine that is made to achieve the right results/performances in the right time, expected by a professional. A machine that is made to last in its performances and lifetime.

Precision: A machine that has been made with precision. A machine that is accurate in its reading, and which provides precise results.

Simple: A machine that is simple, comfortable to use. A machine that goes to the essential of its function. A machine that is just right for itself. A machine that have not been made in comparison to other machines, trying to achieve more. A machine that has been designed and manufactured to answer 100% of the real needs and expectations of users.

Qualitative: A machine that is perceived as good/high quality by people, because it is made of the right choice of materials, process, and finishes, to maintain its appeal & functionality over the time. It also provides a pleasant user experience because of touch feeling of materials.