Mock-up & prototyping, or why physical models are the best tools

3D files allow us to design and visualise products with great precision. But 3D files are often misleading and when moulds are done, any late found problem usually leads to huge loss of time and money.

But thanks to a relevant testing strategy and the right mock-ups/prototyping stages, we can avoid more than 95% of problems. For example, it is impossible to verify that a product is truly ergonomic or really working without testing it in real life. Testing the stye is also essential, as tiny details that are visible in 3D are in fact often too small to be seen/perceived in real life. Mock-ups solve those problems, as we can test the design and optimise it. With prototypes, complex technical problems can be more easily identified and new solutions can be found and validated. We can also validate all the parameters of a product before creating the moulds, which is essential to avoid massive loss of times and money.

Our approach

We are working with an international iterative design process. Therefore, each stage is validated and approved before going to the next.

Having those regular check points is the best way for you and us to control the progression of the projects. At each stage, we give you our explanations, justifications and recommendations, as industrial design must remain pragmatic at all times and in regards of objective criteria.

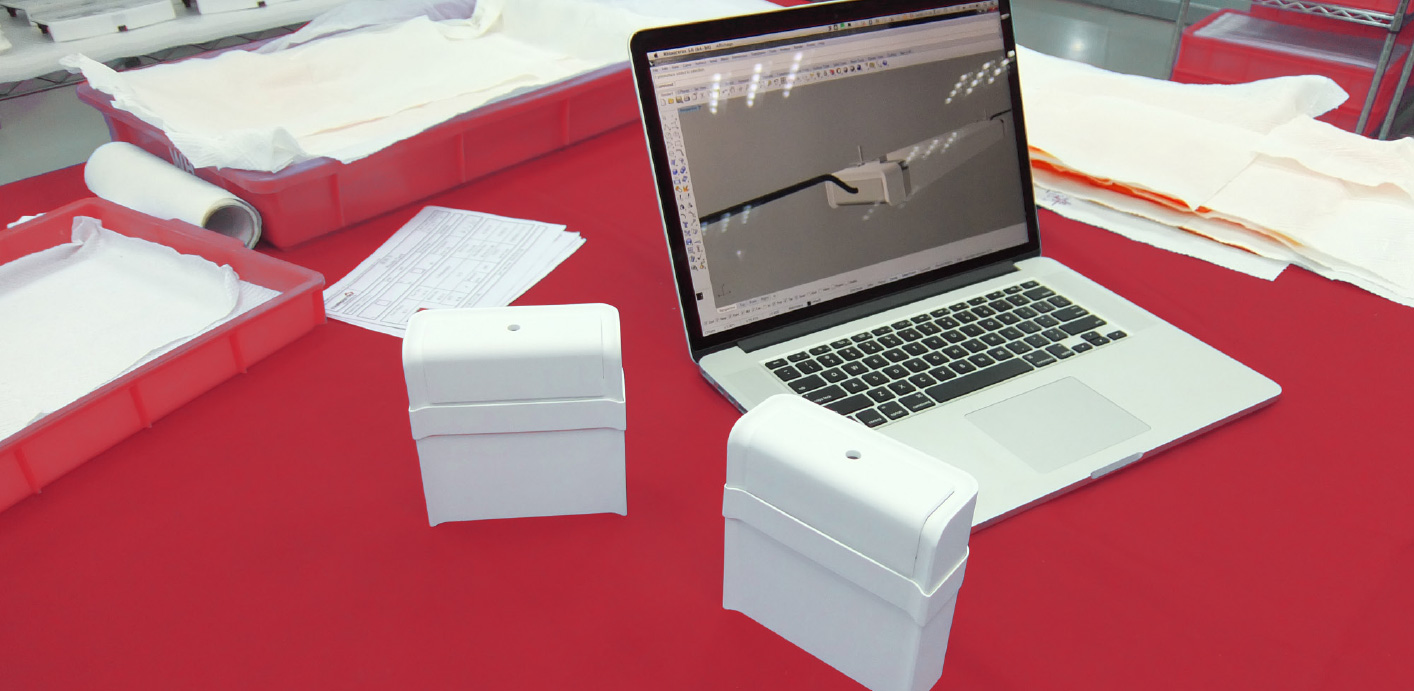

Here is a typical mock-up analysis for a portable hand sanitizer. The client wanted 100ml capacity. We told him it would be too big for a handbag… And we were right.

From left to right, pictures of the first mock-up of 100ml capacity (picture 1 and picture 2), in the hands of an asian woman with small hands (around 150mm). The product size is OK for an indoor use and the shape is ergonomic. But for a handbag or a coat pocket, it is way too big.

The client agreed with our analysis and we did several 3D versions of the product, with different sizes and capacity. We printed them on paper at scale 1 before ordering a new mock-up.

Picture 3 (on the right) is the final result, with a capacity of 60ml.

100ml initial mock-up closed.

100ml initial mock-up opened.

From left to right: 100ml initial mock-up / final colour mock-up / second mock-up.

3 kinds of models

The mock-up / prototyping service is used at different stages of the entire process and involves different kinds of models, so it is very important to carefully select the right kind of model for the right reason at each step.

The foam / grey mock-up

A cheap model, easy to make in foam or plastic. It is used to check shapes, sizes, proportions and ergonomics.

Grey mock-ups are usually done during the creative research.

The colour mock-up

An intermediate model, easy to make and a bit more expensive. It is often in late stage of industrial design to check style, shapes, sizes, proportions and ergonomics.

Colour mock-up are usually done during the design finalisation.

The prototype

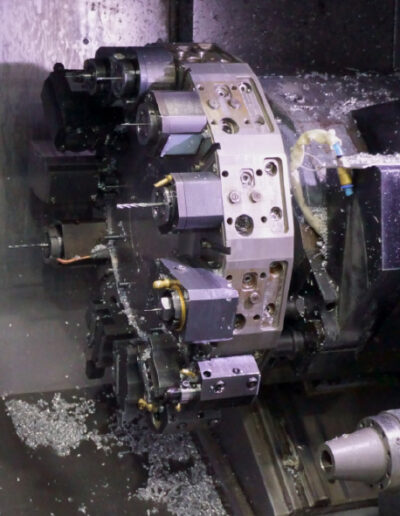

An advanced model that is more expensive to make and usually done at different stages during the engineering and trial production. There are many kinds of prototypes, as some can be made only to test some elements of the future product.

Prototypes can be used to check the same things as mock-ups, but also: features, specifications, noise, resistance to shocks, durability, weight…